Typical Mechanical Properties (Die Cast):

|

Ultimate Tensile Strength(Mpa) |

Yield Strength(Mpa) |

Elongation:% in 2" |

Hardness:Brinell |

|

359 |

283 |

7 |

100 |

Typical Physical Properties:

|

Density(g/cm³) |

Melting Range(°C/°F) |

Electrical Conductivity:%IACS |

Specific Heat (J/kg·°C) |

Die Shrinkage(in/in) |

|

6.8 |

379 - 390 (715 - 734) |

25 |

419 |

.007 |

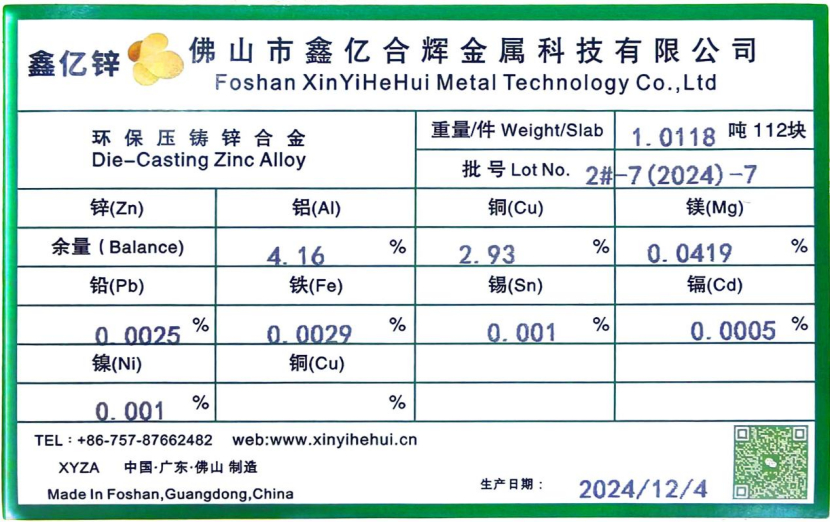

Chemical Specification:

|

% By weight |

Ingot |

Casting |

|

Al |

3.9 - 4.3 |

3.7 - 4.3 |

|

Mg |

.03 - .06 |

.02 - .06 |

|

Cu |

2.7 - 3.3 |

2.6 - 3.3 |

|

Fe(max) |

.02 |

.05 |

|

Pb(max) |

.003 |

.005 |

|

Cd(max) |

.003 |

.004 |

|

Sn(max) |

.0015 |

.002 |

|

Ni |

- |

- |

|

Zn |

Balance |

Balance |